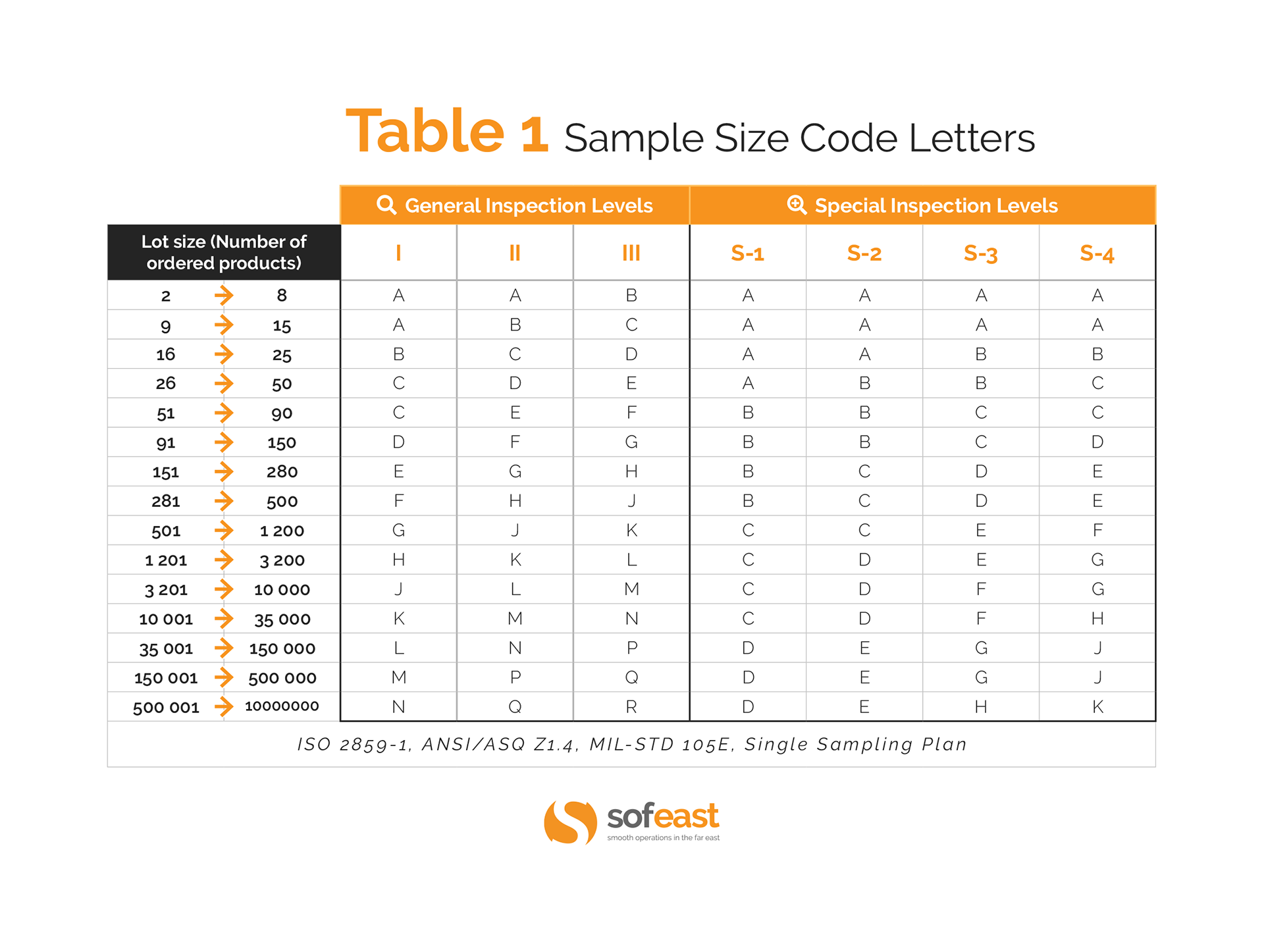

Each ‘AQL table’ is a fundamental tool for preparing a sampling plan for a random product inspection. They give you the number of samples to inspect, and the maximum numbers of defective samples that are allowed.

How to read AQL tables (the 2 most common)

The first AQL sampling table gives you the code letter for sampling. In this example, if the batch to check contains 5,000 pcs, and if you choose level II (which is chosen by default for most inspections), the letter is L.

The second AQL table (for normal severity) gives you useful information. The letter L means 200 samples must be checked. If you select the limits as 2.5% for major defects and 4.0% for minor defects, you reject the batch if you find more than 10 major and/or more than 14 minor defects.

These tables come from military standard 105E, which has been replaced by the ISO 2859-1 standard and the ANSI-ASQ z1.4 standard, among others.

More info about the AQL

To understand the concept of the Acceptance Quality Limit (AQL) in depth, you should read this article.

And here are the original AQL charts (for normal severity), straight from the ISO 2859-1 standard:

Set your AQL easily with our calculator

We have an easy-to-use AQL calculator which makes it simple to get the sample size and permissible defects for your quality inspectors.

Click here to read even more about the topic of acceptance quality limit (AQL).

Get help with quality assurance

Take a look at Sofeast’s quality assurance solutions where we support importers who are working with Asian suppliers with a full range of quality checks and activities.